Biosecurity for the world’s most remote construction site

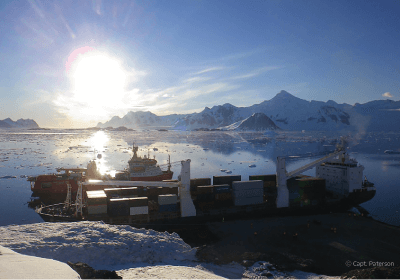

The Trans Global Projects Group successfully led project logistics management for a shipment to the British Antarctic Survey’s Rothera Research Station.

The challenge: Supplying Antarctica while protecting its fragile ecosystem

Our client BAM, a global construction and engineering company, was commissioned by the British Antarctic Survey to remove an existing wharf in Antarctica and build a new one for the Rothera Research Station to accommodate the UK’s new state-of-the-art polar research vessel RRS Sir David Attenborough.

Construction in a remote, harsh environment such as Antarctica came with a unique set of challenges. For starters, virtually every scrap of construction material needed to be brought in; running to a local hardware store for extra screws or paint wasn’t going to be an option! Although importing supplies was necessary, cargo could only be sent during the Arctic summer – the only period when ice restricting sea traffic begins to melt.

Additionally, Antarctica’s environment was also a primary concern. The polar region has a sensitive set of ecosystems that can be threatened by non-native species of plants, animals and bacteria, and as a result, the location has some of the strictest biosecurity regulations in the world. And a breach would have placed BAM’s future Antarctic contracts at risk, not to mention the pristine environment of Antarctica.

Faced with limited resources, a tight timeline and strict regulations, BAM needed all supplies and equipment necessary for their wharf project sent on a single vessel charter, without any margin for error.

And that’s where we stepped in.

Our solution: Biosecurity know-how & proactive planning for single charter transport

To consolidate, supply and ship all the materials needed for the wharf project, our team coordinated closely with BAM, and our biosecurity logistics were multifaceted and exhaustive.

Prior to loading the cargo on the vessel, our experts managed decontamination at a specially prepared facility at Teesport in Teesside, UK. After deep cleaning and spraying the facility, the experts inspected and washed the cargo using ultra-high-pressure water jets. Then, they treated the cargo with the necessary insecticides, fumigated all containers and loading equipment and used timber compliant with the International Standards for Phytosanitary Measures No. 15 (ISPM15) for packing. The chartered vessel itself also went through an extensive decontamination process.

During the lead-up to the sail away date, the expected volume of cargo increased by more than 50%, and our team addressed the client’s needs proactively, while still adhering to strict biodiversity requirements.

Despite the increase in cargo volume and the obvious capacity constraints of the vessel, we were able to keep the impacts on cost and time frame to an absolute minimum. Overall, 13,000 cbm and 85 containers of cargo were prepared and loaded on the ship.

The results: Celebrating New Year’s with a successful delivery

The vessel departed Teesside at the end of November and arrived in Rothera at the end of December. Discharge was complete by the beginning of January, and our team rang in the New Year with another project successfully completed.

References:

https://www.bas.ac.uk/polar-operations/sites-and-facilities/facility/rothera/